FINE™/Marine

The leading CFD software for naval architects and marine engineers

Naval architects and engineers need the best tools for the job, and that’s why Cadence has created CFD software that functions as a virtual towing tank, with built-in automation features, designed specifically for the marine industry.

FINE™/Marine offers a powerful, customized graphical user interface, with integrated marine-dedicated features, for the simulation of mono-fluid and multi-fluid flows around any kind of ship, boat or yacht, including various types of appendages.

Thanks to the C-Wizard, set-up of calculation matrices for different speeds, angles, sea conditions or even geometrical variations can now be accomplished in a completely automated way.

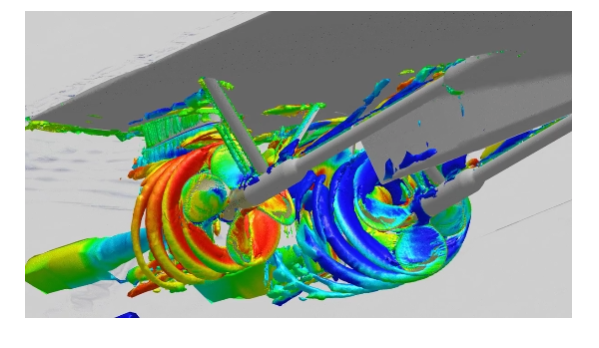

Ship Propeller Analysis Using OMNIS Marine

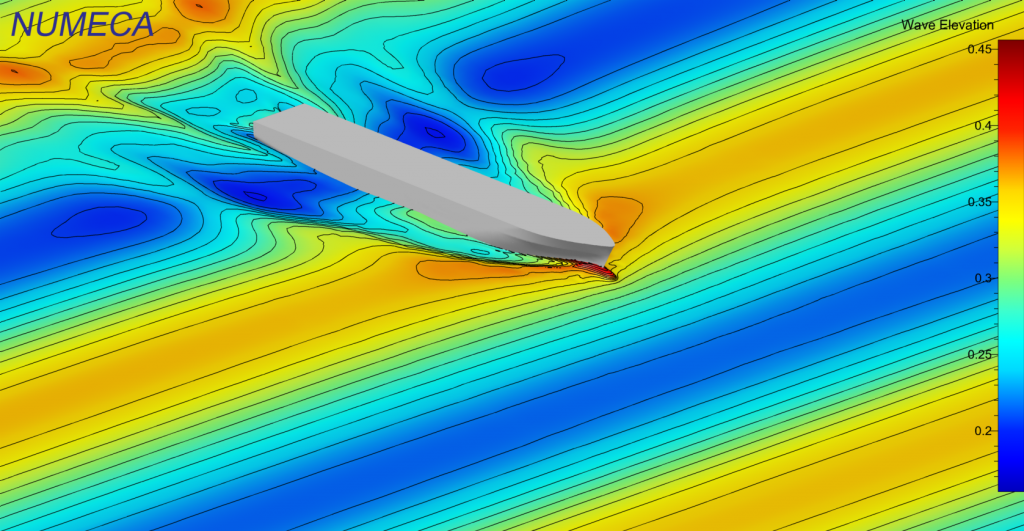

Ship Half Body Analysis Using OMNIS Marine

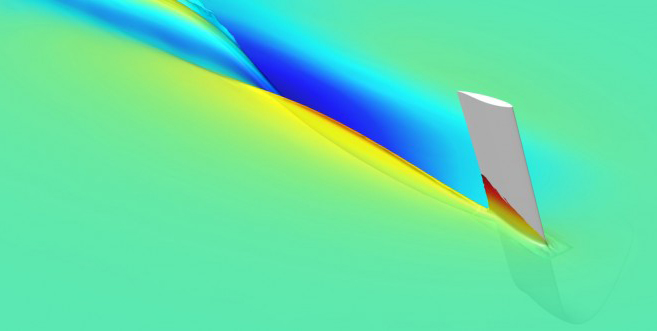

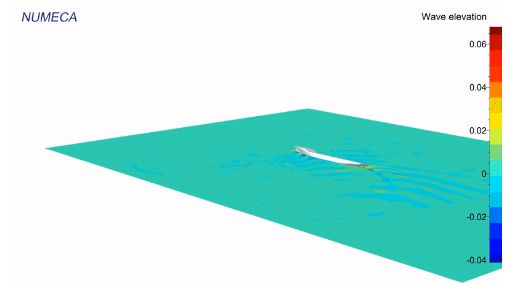

Free surface flows

FINE™/Marine can be used as both a virtual towing tank and virtual wind tunnel. It has been developed with total focus on flows involving free surface. This requires efficient free surface modeling taking into account both water and air, appropriate turbulence modeling, and efficient grid adaptation.

The Volume of Fluid (VOF) approach is used, while grid adaptation and refinement are applied to follow the free surface time evolution and the hull relative motion.

Different time models are available, steady, quasi-steady and unsteady, with always a focus on the most effcient initialization algorithms to minimize the total computing time.

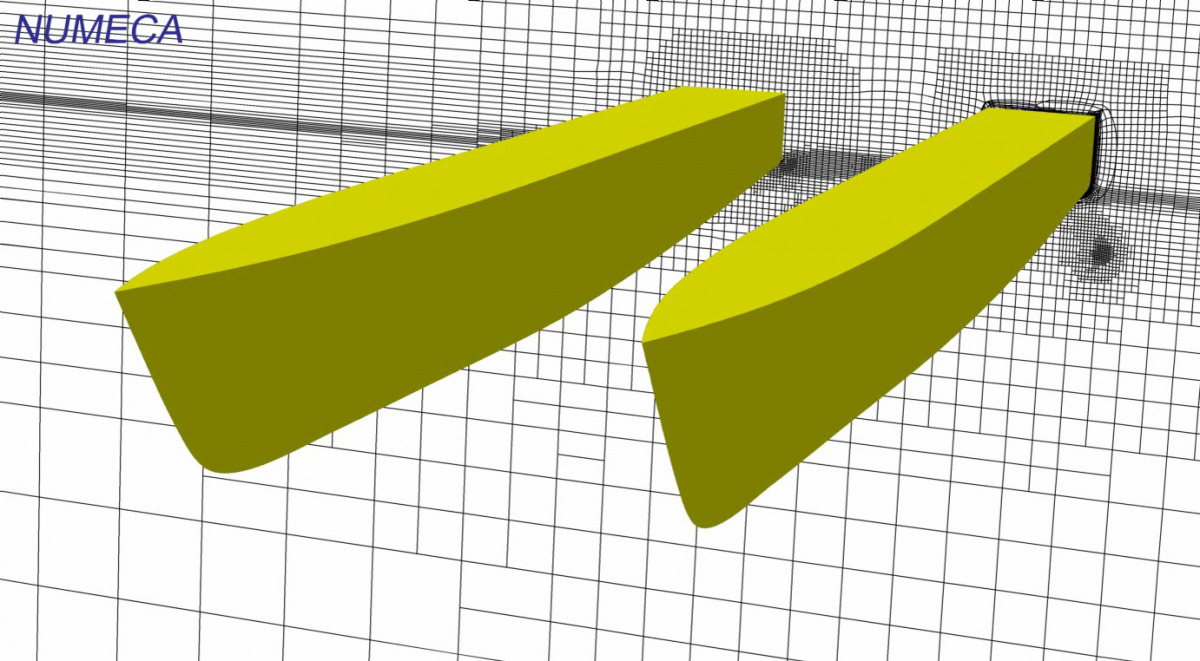

Adaptive mesh refinement and overset grid method

FINE™/Marine features a variety of mesh strategies for bodies with motions: weighted mesh deformations (ship trim and sink); sliding grids (propeller rotation); and overset grids (complex motions, appendages).

Overset meshing has clear advantages for parametric studies, and is essential for large movements.

Adaptive grid refinement refines free surface during calculation and allows for different operating conditions to be calculated in one single mesh.

The unique compatibility of overset meshing with adaptive grid refinement in FINE™/Marine ensures mesh continunity and reduction of numerical error within the two overlapping meshes.

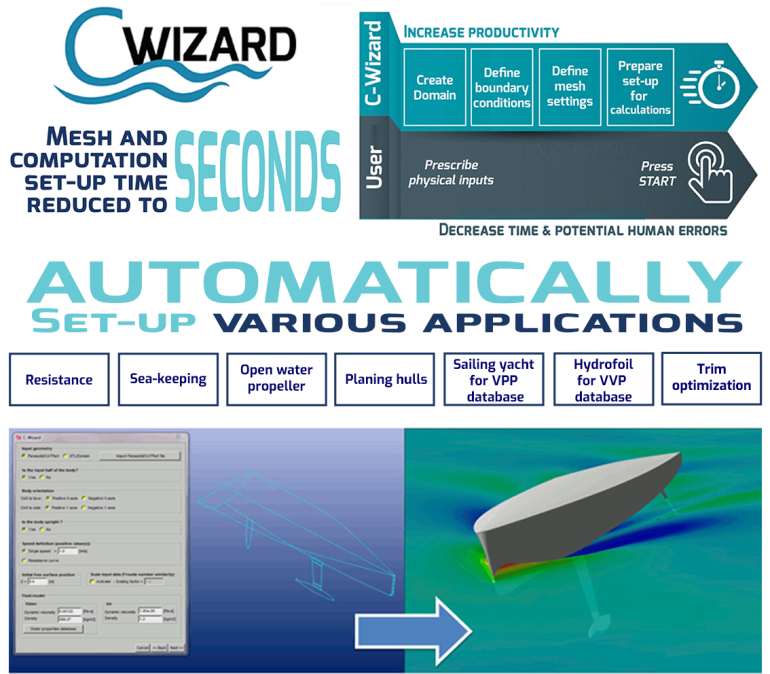

Automatic set-up of the CFD chain with C-Wizard

The C-Wizard drastically reduces engineering time for complete CFD simulation set-up through an automated process.

It uses all the scripting tools from the interface to automatically set up different applications, such as:

• Resistance at low and high Froude numbers

• Seakeeping

• (Self-)propulsion

• Planing hulls

• VPP

• Trim optimization

All kind of boats are eligible for the C-Wizard: tankers, containers, high speed crafts, sailing or luxury yachts, even hydrofoils and open water propellers.

No need to spend time on setting numerical parameters. By specifying the physical inputs only, users receive a complete definition of the required simulations, including numerical aspects.

Rhino plug-in for a seamless workflow

Thanks to the Rhino plug-in for FINE™/Marine, CAD models can be exported from the Rhinoceros interface directly to C-Wizard or to our meshing environment, hasslefree.

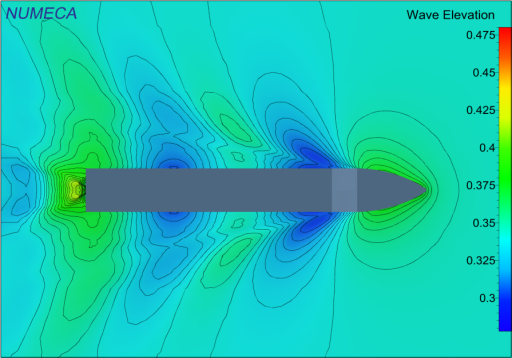

Resistance

Resistance calculation is a standard in FINE™/Marine and can be set up automatically with the C-Wizard.

Thanks to Cadence’s convergence booster and various methods like sub-cycling, quasi-static and multigrid for the pressure solver, the RANS solver speeds up calculations for resistance cases up to 5x times.

FINE™/Marine is recognized by its peers to be the software-reference concerning accuracy.

Propulsion

Several options are available for the modeling of propellers and the interaction of the propeller with the hull and appendages.

The dedicated C-wizard for the design of open propellers fully automatically organizes the meshing and solver set-up with appropriate boundary conditions.

Large validation experience shows the importance of:

• Actuator disks for quick and accurate global trends

• Sliding grid approach for detailed propulsion analysis

• Turbulence modeling: from standard K-W to advanced DES models

• Ventilation and cavitation modeling

Seakeeping

Model regular, irregular or user-defined waves.

Especially in cases of strong waves of high amplitude, grid deformation algorithms are often challenged. FINE™/Marine has been tested on many configurations, and essential modules have been implemented, such as:

• Wave initialization

• Good wave damping strategy

• Adaptive grid refinement

• Overset capability

Waves can be generated from boundaries, or by using internal wave generators. Algorithms have been developed to ensure the damping of the waves as they evacuate the domain, rather than being numerically reflected.

Maneuvering

Complex motion simulations at model and full scale can easily be achieved with dedicated approaches for maneuvering applications like:

• Zig-zag

• Turning circle

• Coursekeeping

• Pure sway

• etc…

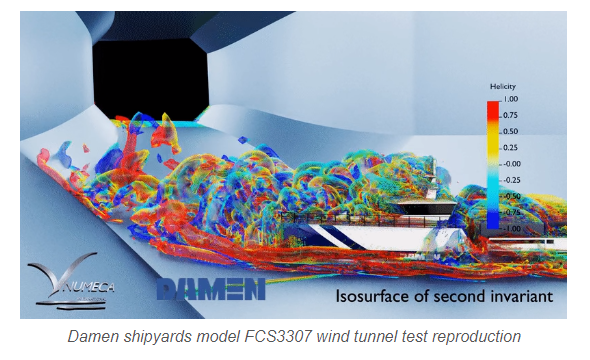

Wind studies for ships

FINE™/Marine’s capabilities for wind studies around ships enables naval architects to replace wind tunnel testing with CFD.

This area of ship design has become of prime interest for passenger comfort.

No time needs to be spent on the geometry of the ship superstructure, thanks to Omnis™/Hexpress and AutoSeal.

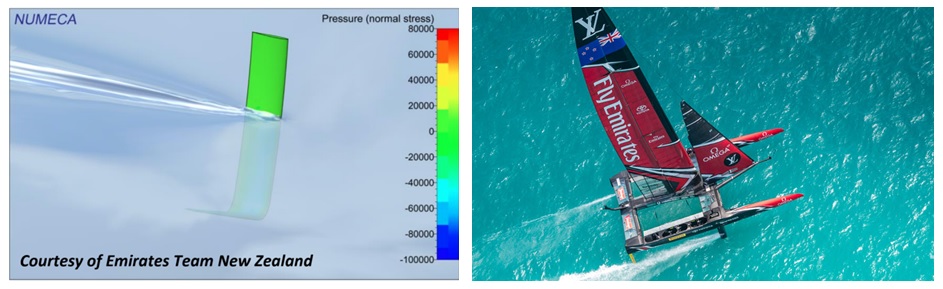

VPP (Velocity Prediction Program) for sailing yachts and hydrofoils

The VPP (Velocity Prediction Program) matrix in C-Wizard enables users to calculate performance of sailing yachts and hydrofoils.

Cadence has accumulated years of experience in efficiently organizing matrices of runs in a user-friendly way. Scripting can easily be implemented to spread the runs and collect the results, so users can focus fully on understanding the physics.

Optimization

FINE™/Marine can be combined with FINE™/Design3D to enable ultra-efficient design optimization.

Parametrization is a breeze thanks to the Grasshopper tool available from within Rhino.

Various objectives can be defined for ship optimization. For example:

• Decrease ship drag in calm sea or in waves

• Reduce dynamic trim angle amplitude for passenger comfort

• Improve propeller efficiency to reduce the required power

These objectives can be checked for several speeds or loading conditions.

An interesting example: hull shape design optimization saved this ferry company USD 337,000 per year and reduced fuel consumption by 13%.

“Having been involved in developing different concept designs in the past 2 years, we cannot stress enough the importance of small hull optimisations. Cadence’s FINE™/Marine is the perfect tool for the job. We can now confidently deliver the most efficient design for any set of requirements, be it in the displacement or planning regime.”

Liviu Galatanu, Director of BD & Integration at GLO Marine

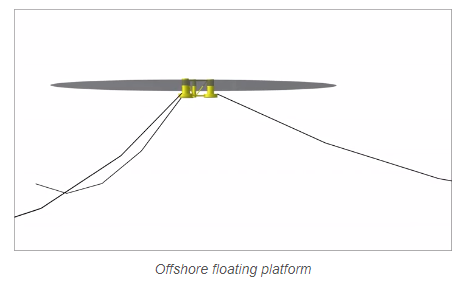

CATway module for cable dynamics

A new advanced cable module is now available directly in FINE™/Marine. This module can be used for a variety of applications, including:

• Ship towing another ship or a fish, buoy, etc.

• Mooring lines for ships attached to the ground or to the dock

• Cranes winch for objects delivery

• Offshore floating platform

Key features

Mesh generator (Omnis™/Hexpress)

• Non-conformal, fully hexahedral meshes

• Viscous layers insertion with inflation method

• Thin surfaces modeling (sails, trim tabs…)

• Replace geometries module

• Limited user inputs – high degree of automation

• Fully scriptable

FINE™/Marine’s Flow Solver

• Highly accurate free surface capturing

• 6DOF with marine dedicated motion laws

• Quasi static approach for all kinds of boats and hydrofoils

• Sub cycling acceleration

• Adaptive grid refinement

• Sliding grid interfaces

• Overlapping grid

• Cavitation modelin

• Mooring and tugging line

• User defined dynamic libraries (forces and motions)

Graphical User Interface (FINE™ GUI)

• Marine dedicated environment

• Fully scriptable

• Wizard for mesh and computation setup

Post processing (CFView™)

• Marine dedicated add-ons (free surface elevation, forces by section, propeller wake flow analysis, wetted area, represent towing tank lines, etc.)

• 3D streamlines with lines, tubes and ribbon representation

• 1D data to compare with experiments

• 2D and 3D data like scalar and vector fields

• Cartesian plots

• Cutting planes

• Fully scriptable

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.

Pars Makina

We provide reliable, economical, high-power and efficient innovative solutions in the fields of Transport, Defence, Aerospace, Aerospace Engineering and Clean Energy.