OMNIS™/HEXPRESS

Fully unstructured hexahedral meshing with hex dominant mesh options for complex geometries

Omnis™/Hexpress can handle any possible geometry, no matter how complex. High quality meshes are produced at speeds of up to two orders of magnitude faster than competitive products.

Omnis™/Hexpress includes access to HEXPRESS™/Hybrid.

Drastic reduction of engineering time

Thanks to AutoSeal, users avoid spending time on CAD cleaning and repairing.

“Where a skilled engineer typically needed one full week to close all the holes of the cabin space before, now this whole process is brought down to just about one hour.” Akio Takamura, Chief Engineer at Honda Automotive

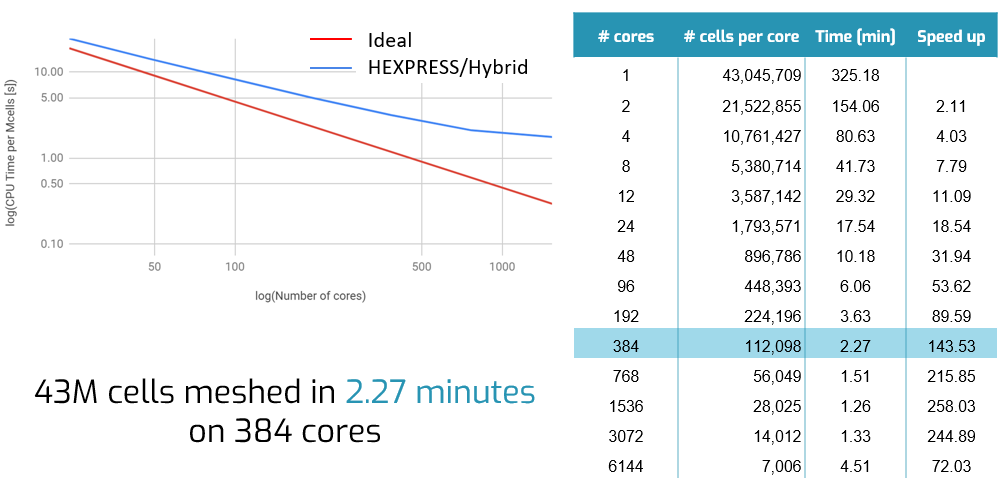

To speed up the process even further once the CAD is prepared, Omnis/Hexpress’ unique capability to mesh in parallel on distributed memory allows for meshes to be generated on several computer or clusters at the same time. As a result, millions of cells can be created in minutes.

Choosing the best meshing algorithms, case by case

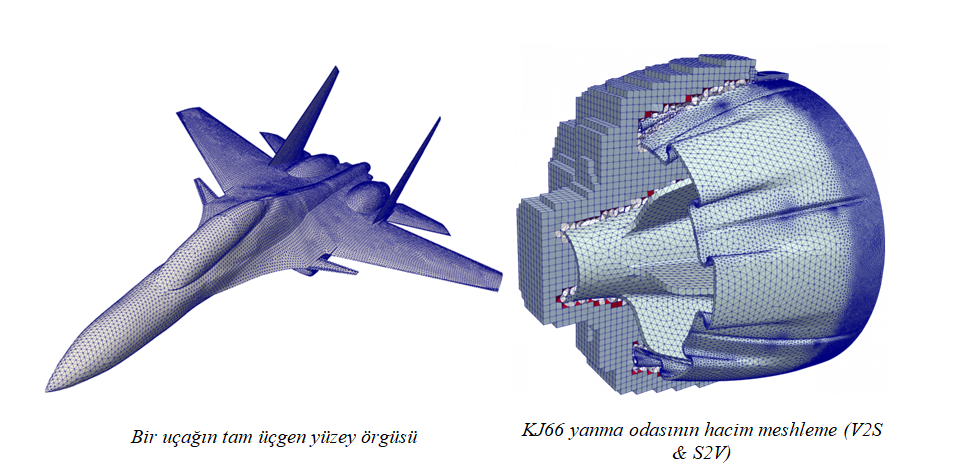

Omnis/Hexpress not only offers the choice between a Volume-to-Surface (no surface mesh required) or Surface-to-Volume approach, but allows for a combination of both. This mesh generator is the only one on the market to propose a complete tool kit with all best-in-class volume meshing algorithms, including:

• Full hexahedral meshes with hanging nodes

• Hex dominant meshes without hanging nodes

• Full tetrahedral meshes

They even work on non-conformal and not-watertight CAD geometries.

For surface mesh generation, it offers Full Triangles or Quad-dominant.

Efficient flow simulation workflows

Omnis/Hexpress is available as a standalone or bundled.

Within our Omnis environment users can easily couple their own flow solver to our meshing technology and take advantage of a highly streamlined workflow.

Complete automation of the workflow from A to Z is made possible with the Python plugin API.

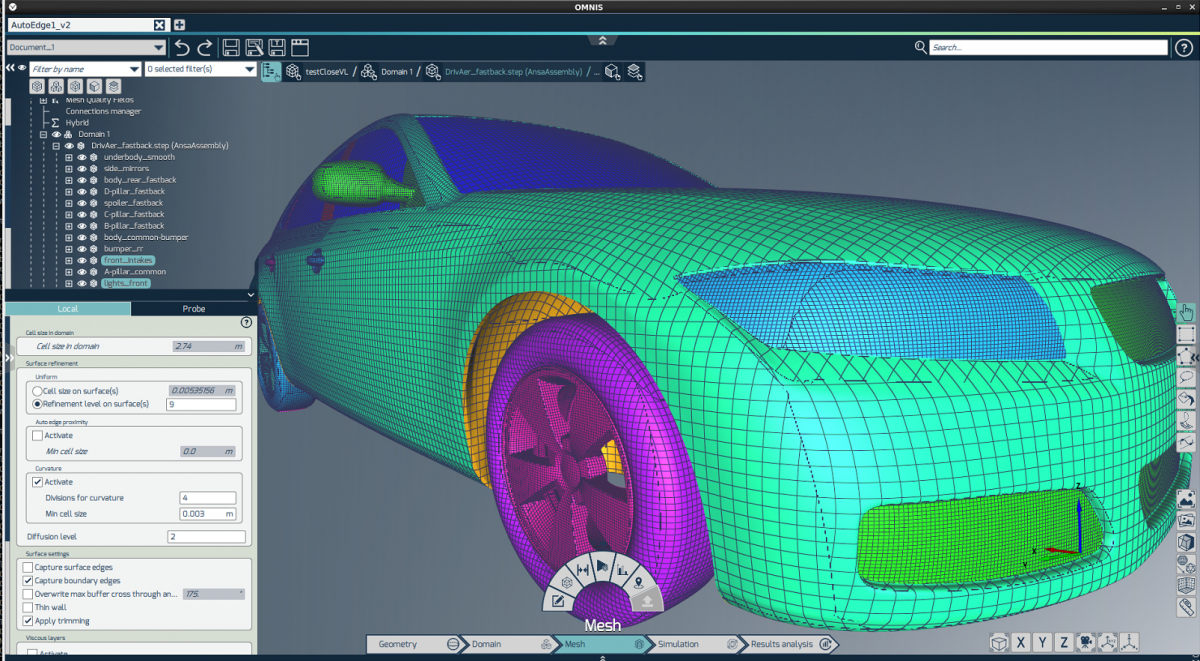

Instantaneous mesh previewing with on-the-fly texture mapping gives a quick preliminary sneak view of the mesh before even starting the grid generation process.

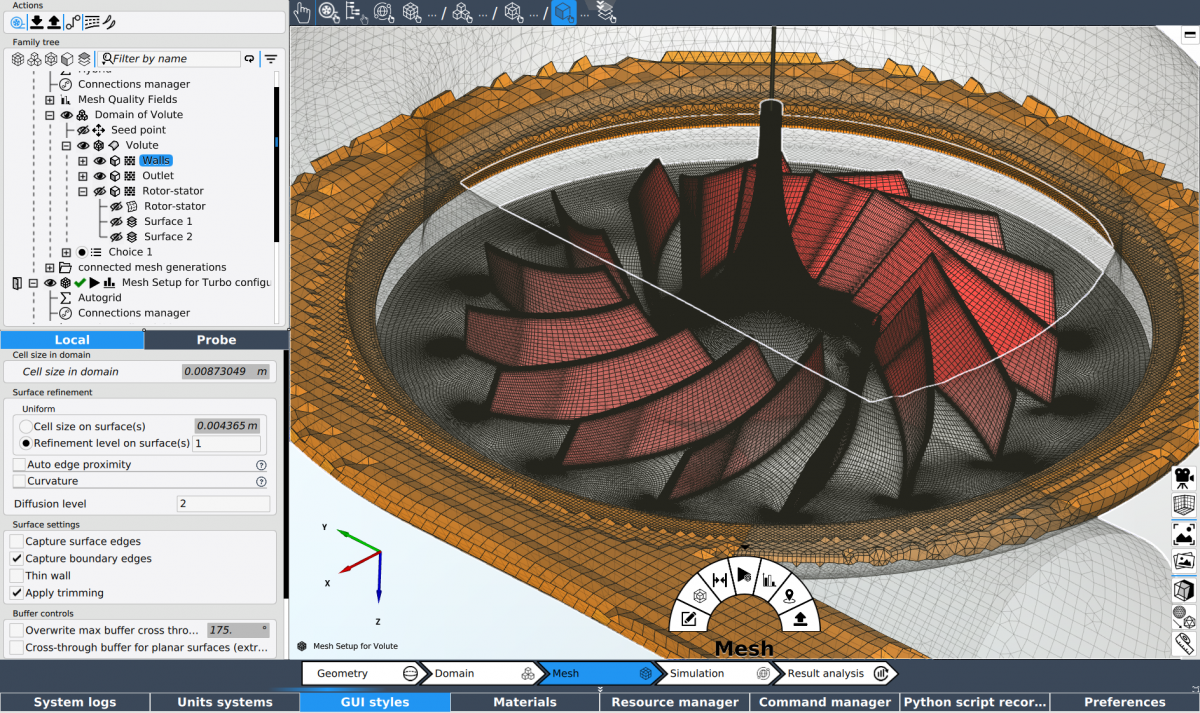

Structured & Unstructured seamlessly combined

Within Omnis, mesh generation methods can be combined to benefit from the best of each technology, combining high-fidelity with speed

• The structured automatic, multi-block meshing tool Omnis/AutoGrid for structured meshes, offers unsurpassed speed and accuracy for rotating equipment.

• Omnis/Hexpress provides high-quality unstructured meshing for even the most complex geometries.

Different methods can be used per domain of simulation or at different places of the same object and connected via non matching connections.

Viscous layers insertion

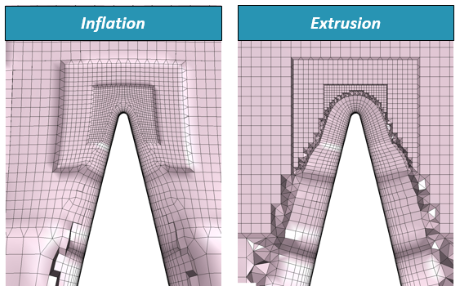

Volume meshing includes high quality viscous layers insertion with inflation or extrusion method, ensuring the best possible transition for the turbulence. A combination is also possible, the user can choose the best option for each surface in the geometry.

The inflation method is compatible with full hexahedral and hex dominant meshes. In this method, the first boundary layer from the Euler mesh is inflated (pushing away the other cells) and the viscous layers are then inserted. It creates an excellent transition between the last layer and the Euler mesh.

The extrusion method is compatible with hex dominant meshes. In this method, the boundary layer is inserted based on the requested height, removing the cells underneath from the Euler mesh. Viscous layers are then inserted and a reconnection is done with the far field mesh. The advantages are here double: a perfect far field and more constant boundary layer thickness.

Key Features

• Mesh arbitrarily complex shapes: internal/external, CFD & FEM grids

• Full edge capturing on user request

• Robust and integrated CAD cleaning and hole closing

• Small gaps and overlaps automatically resolved

• Large gaps detected and closed with AutoSeal

• Volume to surface approach, with pure Tet, Hex or Hybrid meshes

• Batch or Interactive GUI-fully scriptable

• Surface mesher, with triangles or quad dominant cells

• Surface to volume approach, with Tet or Hex dominant meshes

• Flexible viscous layers insertion with smooth transition

• Meshing of multiple volumes with matching connections in one step

• Meshing of thin-surfaces (heat shields, exhaust pipes, etc)

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.

Pars Makina

We provide reliable, economical, high-power and efficient innovative solutions in the fields of Transport, Defence, Aerospace, Aerospace Engineering and Clean Energy.