INNOSOLPOWER PROJECT

Call: H2020-LC-SC3-2018-2019-2020

Project No: 838311

Project Partners: Pars Makina, Kane Cres, Middle East Technical University, Universita di Pisa

InnoSolPower: “INNOvative SOLar micro-TES with high-POWER density“

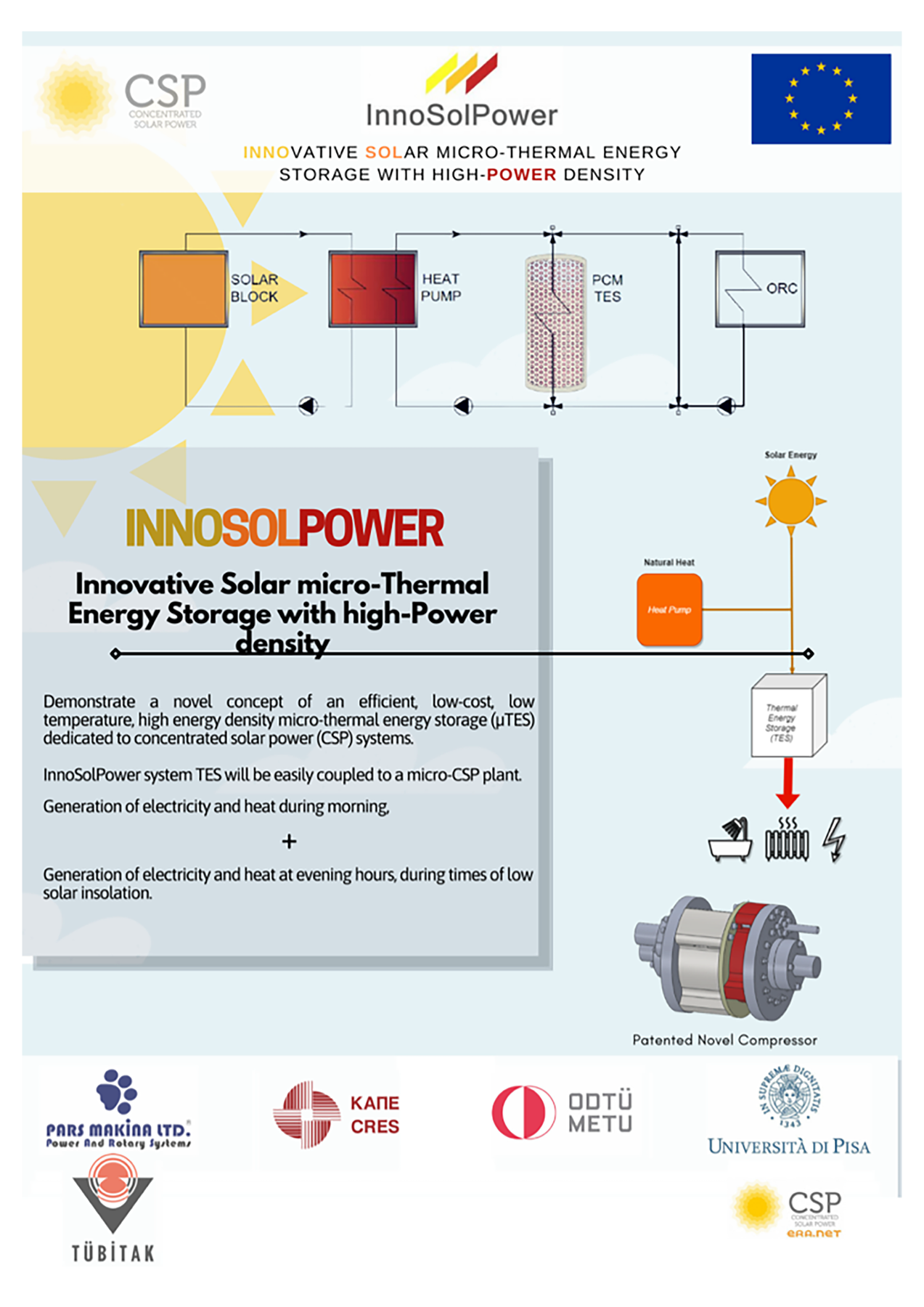

The project aims to demonstrate a novel concept of an efficient, low-cost, low temperature, high energy density micro-thermal energy storage (µTES) dedicated to concentrated solar power (CSP) systems. The ultimate goal of the project is to develop and test an efficient TES with a higher than ambient heat pump (HP) heat transfer fluid (HTF) inlet temperature achieved with a solar CSP. The new TES will achieve a large TES storage density, minimum response time, highest roundtrip efficiency and cost viability. The objectives of the project will be realised through the following steps:

1) Selection of high-power density TES material. Proposed HTF is a state of the art, environmentally friendly refrigerant. Water is used as reference TES phase change material (PCM). Final solution is a high-power density TES with an optimised HTF and heat exchanger architecture. Concentrated Solar Power InnoSolPower – ID: 12 3 of 40

2) Testing of main subsystems and components. A novel, efficient rotary arc vane compressor for HP is introduced.

3) Integration of the µTES with a kW-scale CSP plant, incorporating a heat pump (HP) and a discharge heat exchanger (HX) that is present at an ORC (not included in the project) input.

4) InnoSolPower prototype will operate in a relevant environment.

5) Detailed cost reduction analysis and impact analysis in LCOE. The project starts from a laboratory (TRL 4) level and the consortium brings the product development to TRL 6 or higher. This costcompetitive thermal energy storage product with superior thermal performance and smaller space requirements is expected to capture a significant market.

InnoSolPower system TES will be easily coupled to a micro-CSP plant,

• Generation of electricity and heat during morning and,

• Generation of electricity and heat at evening hours, during times of low solar insolation,

• Initial capacity factor of near 30%. CSP + TES,

• Nominal thermal power rating of 10 kW and 6 hours of thermal energy storage,

• Contribution to achieve an aggressive LCOE of 6¢/kWh for CSP plants.

TIDALHEALTH PROJECT

Call: H2020-SMEINST-1-2014

Project No: 663953

Project Partners: Pars Makina, Transense, Brunel University

TIDALHEALT; “Health Condition Monitoring of Small Scale Tidal Generators Using Miniature Torque Sensors”

Tidal energy production is expected to increase significantly in the next 5-10 years as the production costs of tidal energy decrease and technological developments emerge.

Tidal generators are installed in very harsh environments of the seabed, where salt water, unpredictable tidal flow, marine litter and hanging particle effect can cause serious damage to generator blades and gearboxes. In addition, the unpredictable changing nature of load demand causes stresses on tidal components. The primary objective of the TidalHealth project is to commercially produce a direct torque meter connected to the tidal generator shaft to remotely monitor the overall condition of tidal power plants. This will result in reduced operating and maintenance costs of the facilities, thereby improving the return on investment for tidal technologies.

The purpose of TidalHealth technology is to improve the health monitoring system of tidal generators using torque sensors connected to generator shafts. This system will be able to reduce the operating and maintenance costs of tidal power plants and thus successfully commercialize the tidal energy market. With the developed system, a potential marine energy market is targeted with some features such as the optimal mounting method of the RF antenna for data communication, miniature sensors that take measurements directly from the torque inlet.

SUNFLOWER PROJECT

Call: FP7 Manunet

Project No: 9120045

Project Partners: Pars Makina, Enecom, Stam

SUNFLOWER; “Development of a Totally Passive Photovoltaic Solar Tracker”

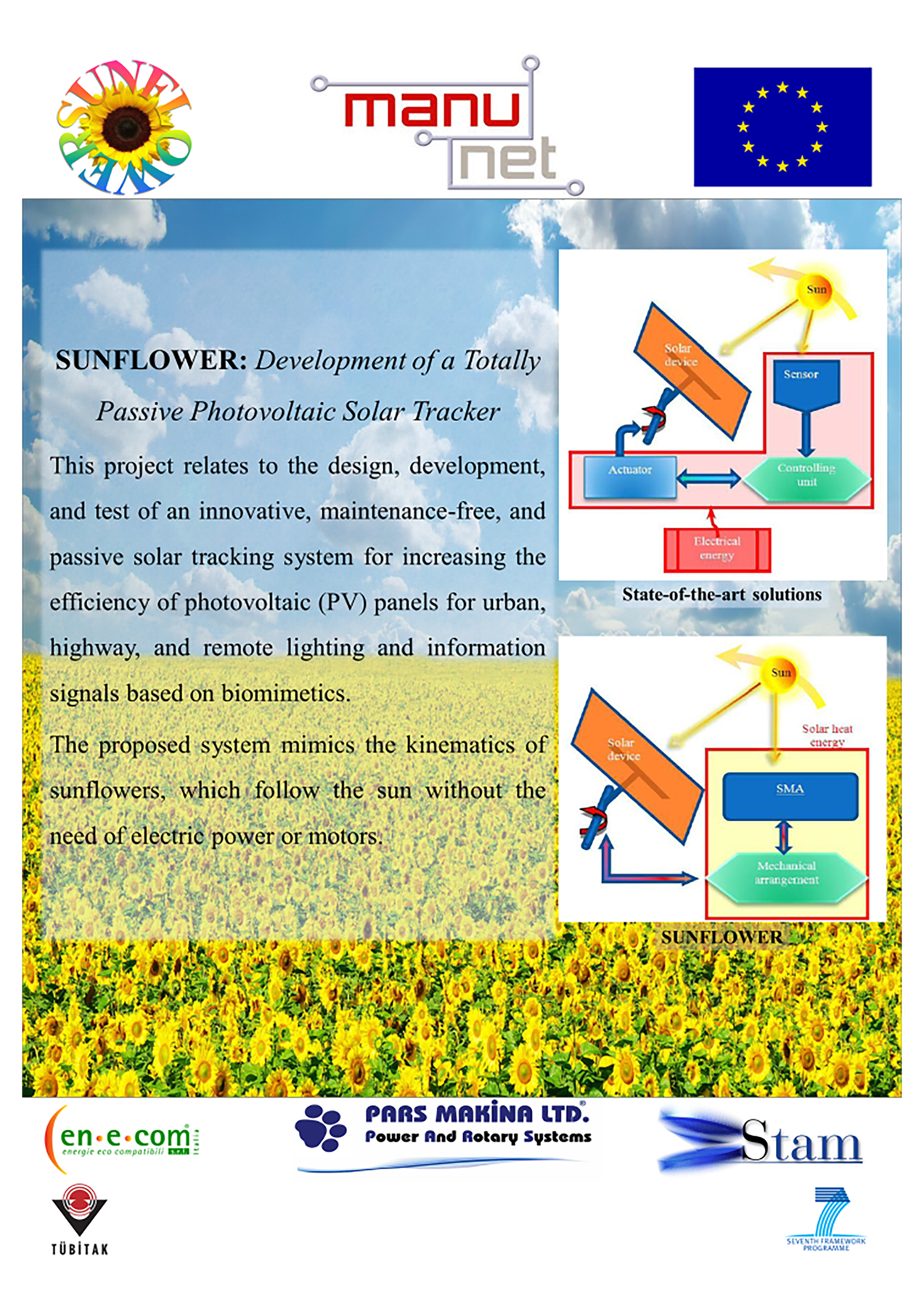

Identifying and exploiting sustainable energy sources to satisfy the world’s growing demand is one of society’s foremost challenges for the next decades. In particular, the efficiency in converting sunlight to electricity via photovoltaic solar cells is a paramount contribution to dramatic reducing cost (price and ecological impact) of electricity. The main innovation of the proposed SUNFLOWER system lies in its totally passive nature: in fact the system can mimic the kinematics of sunflowers, which follow the sun without the need of electric power or motors, exploiting the different thermal expansion of metallic heat responsive elements. The objective of the project is to overcome the drawbacks associated to current state-of-the art PV panels, whose power output depends on a number of factors, including operating temperature, irradiance and incident angle of the solar radiation.

The SUNFLOWER technology can be successfully applied to small plants: highway cameras and signalling; urban lighting; water pumping stations; rural development; house micro-generation; space applications etc.

OPTIWIND PROJECT

Call: FP7-SME-2012

Project No: 315563

Project Partners: Pars Makina, Atech Elektronika, Windcrop, Insteler SL, UK Intelligent Systems Research Instıtute, Kliux Energies, GenDrive, Tecnalia

OPTIWIND, “Optimum Power Extraction of Wind Energy by Small to Medium Scale Wind Turbines”

The overall aim of the OPTIWIND project is to further research and develop maximum power extraction technologies that will enable us to improve the energy efficiency of small and medium-sized wind turbines during operation in low wind conditions. It is vital that maximum power can be achieved from the low wind speed range of the turbine. The target final product is intended to produce approximately 20-25% more energy capture for low wind speeds. This will increase the purchase of products and open up more space at the point of use, which will become economically viable for more energy production. It will bring significant economic and social benefits to manufacturers, service and installation companies and contribute to climate change goals.

The following topics were studied in the project:

– Development of a new technology to significantly improve the performance of small wind turbines,

– Optimizing the contribution of wind energy to mains energy by the inverter,

– A real-time embedded system has been designed to maximize energy efficiency.

ICARUS PROJECT

Call: FP7-SME-2012

Project No: 267643

Project Partners: Pars Makina, HRS Heat Exchangers, Türkiye Çimento Müstahsilleri Birliği(TÇMB), The University of Nottingham, Chimar Hellas S.A., European Thermodynamics Limited, Eesti Innovatsiooni Instituut, Tarmac, Novamina

ICARUS, “An Innovative, environmentally friendly CO2/Lubricant Absorption Power System for Highly efficient Power Generation from Low Temperature industrial waste heatto reduce emissions and costs”

The aim of the ICARUS project was to create an absorption power generation technology for low temperature (60-120oC) heat. This would then enable a waste-heat power generation system for industrial (chemical, cement etc.) applications to be created that can generated electricity from industrial waste heat (<120oC) without affecting industrial processes. By doing this, the absorption power generation system created will offer greatly improved environmental performance due to improved efficiency and reduced CO2 emissions at a cost that is affordable to the end-user. This will lead to significant economic and societal benefits to manufacturers.

An initial system specification was generated along with a mathematical thermodynamic model for the ICARUS absorption system. A literature search of potential working fluids was carried out and POE32/C02 was selected for further investigation. The predicted system efficiency was found to be inadequate and consequently it was decide to investigate a pure C02 system. Although the system efficiency of this was calculated to improve, the operating pressure was much higher and the associated potential system costs thought too great. Therefore a selected new refrigerant Organic Rankine Cycle (ORC) power generation system was investigated.

A small scale 5kW prototype system based on the refrigerant was designed and constructed incorporating a selected expander. This was then tested. Although the performance was lower than predicted possible reasons were identified and a set of recommendations to improve the system efficiency proposed.

ECO-BOAT PROJECT

Call: FP7 Manunet Era-Net

Project No: 9100039

Project Partners: Pars Makina, Scanner, ICPE, Stam

ECO-Boat; “Boat equipped with environmentally friendly Diesel/electric propulsion”

The project aims to develop an original boat called ECO-Boat, which is environmentally friendly, energy saving, low energy consumption, highly efficient and economically viable and sustainable.

With the studies carried out, an ECO-Boat system integrated with the compact energy storage system was developed by obtaining some of its energy from the wind turbine, which is a renewable energy source, through the recovery of engine exhaust gas waste heat.

Thanks to these features, ECO-Boat also offers the possibility to travel to protected sea areas that are restricted to enter, biodiversity and wildlife are protected, sensitive and unspoilt.

RECYCLE PROJECT

Call: JTI-CS-2009-2-GRC-03-002

Project No: 267643

Project Partners: Pars Makina, Eurocopter

RECYCLE; ” theRmal Energy reCoverY eleCtricaL systEms “

It is a systematic study of thermal heat recovery for rotor boats, which aims to generate electrical energy from heat losses. These systems reduce the required electric load input from the engine and provide an overall increase in the thermal efficiency of the rotorcraft drive system. It is also to examine how such systems contribute to the cooling of the main drivetrains by pumping heat.

Within the scope of the project, the following studies were carried out;

– Determination and measurement of lenient thermal loss sources of Rotocraft systems,

– Research and examination of potential innovative and new solutions. Thouroughy evaluation of the specific power, specific power density outputs, specific volume and specific cost of such systems. Conducting risk assessments related to Rotorcraft performance, magnetic and electrical interference, flight safety and structural integrity,

– Heat and power balance flowcharts and exerting analysis of heat recovery electrical systems of the most promising candidates. Creation of an energy flow behavior model of each of the systems taking into account a representative helicopter power and thermal networks,

– Development of a detailed simulation and design of a robust rotorcraft power network in saber program,

– Production of the most representative heat recovery electrical generation device model and performance capability verification,

– Mockup potential verification.

COMBINA PROJECT

Call: PIAP-GA-2008

Project No: 230714

Project Partners: Pars Makina, Numeca International, Technische Universitat Darmstadt, Insa Rouen, Technische Universiteit Eindhoven, Middle East Technical University

COMBINA; “COMBustion models for Industrial Applications”

Combustion constitutes the majority of energy transformation processes carried out worldwide. Therefore, accurate modelling of combustion processes is necessary for the realization of existing policy objectives for reducing the increased efficiency and emissions of combustion engines and devices. This project collaborated to develop advanced models for spray combustion that are pre-mixed and partially pre-mixed into fine/open, an unstructured, multipurpose CFD software package.

Models developed for pre-mixed and partially pre-mixed combustion simulation have been validated in a series of understandable test cases, from analytical verification test cases and specific flame configurations for verification to complex, industry-like test cases.

BML is integrated into the hybrid BML/flamelet and FGM model FINE/Open and is made available through a user-friendly graphical user interface (GUI). A Lagrangian module has been developed for simulation of evaporating sprays in FINE/Open. The module dissolves particle parcels and calculates the two-way bonding of mass, momentum and energy between the scattered and continuous phase. The Lagrangian module is partially combined with combustion models for non-mixed combustion so that spray combustion processes can be simulated. Spray combustion modeling function is verified on a number of basic spray flames. It was also used for simulation of two different aircraft engines.

DREAM PROJECT

Call: FP7-AAT-2007-RTD-1

Project No: 211861

Project Partners: Pars Makina, ONERA, TM

DREAM; “ValiDation of Radical Engine Architecture SysteMs”

To reduce values such as engine specific fuel consumption and CO2 emissions, it is to design, integrate and validate new engine architecture (turbo fan engine with rotors rotating in opposite directions without external circles). Open rotors are noisier than turbofan engines with equivalent high bypass rates, so it is necessary to offer solutions to meet noise ICAO certification standards. It is aimed to reduce noise emissions of 3 dB per engine starting point. In addition, alternative fuels were tested to reduce environmentally harmful emissions and gas turbine combustion chamber tests were carried out. Alternative fuels have been shown to be available in modern aircraft and engines. Studies have also tested existing and alternative fuels (XTL type or alge or 3rd generation fuels from Jatropha) that are also in use.

The benefits are as follows:

– No significant changes are required to use alternative fuel in the aircraft or engine,

– Investigation of the advantages of pollutants on their emissions (NOx, CO, HC’s, institutions…),

– Contributing to the reduction of greenhouse gas emissions (CO2 emissions are measured and compared with standard aviation fuel).

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.